Device Bridge

Connecting all machines with one central solution

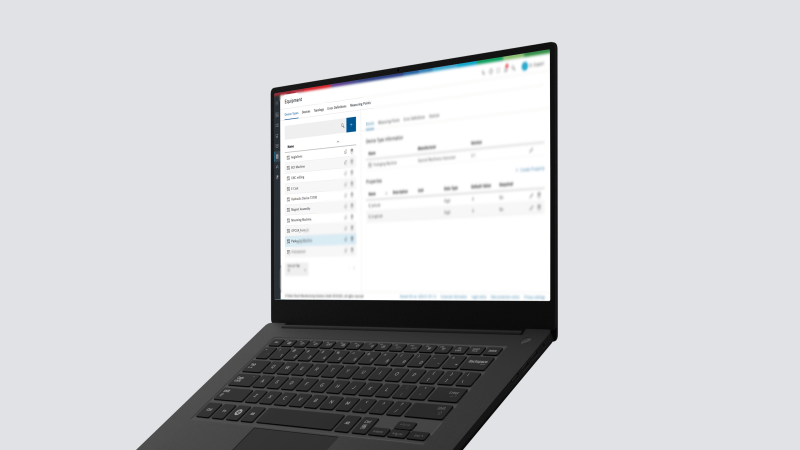

A centralized solution for the collection of all manufacturing data

Benefits at a glance:

Plug & play

for easy configuration and setup

No or hardly any programming effort

at the controls/machine

Data acquisition

almost in real time

Centralized interface between the shopfloor and IT

Real-time data acquisition and processing is critical for all manufacturing processes. One of the main challenges is the heterogeneity of systems, machines, and components. A great deal of programming effort is often required at the control system to establish connectivity in the first place. The software applications that rely on the data must therefore not only process ever larger volumes of data, but also ever more diverse ones.

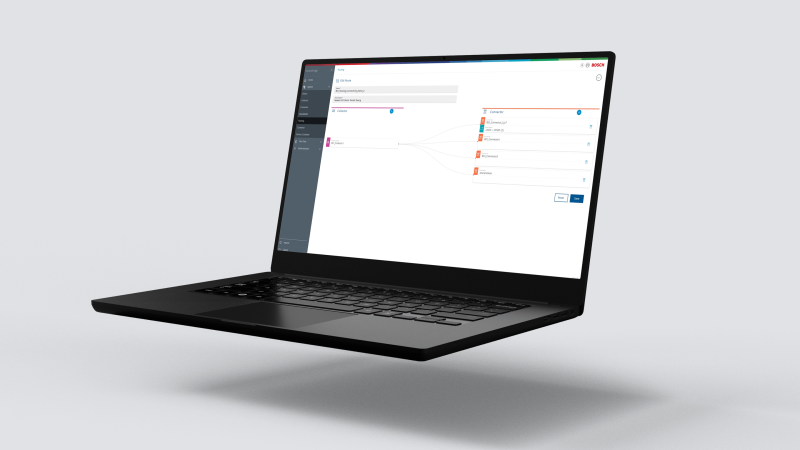

Bosch therefore offers the Device Bridge, a plug & play software solution that captures all incoming manufacturing data, converts it into a standard format, and makes it available to IT applications, such as the Nexeed Industry Application System. The data transfer runs almost in real time and includes additional, useful functionalities, such as (intermediate) storage, analyses, monitoring, and notifications in case of malfunctions. All connected software applications benefit from the high response speed and optimized data availability.

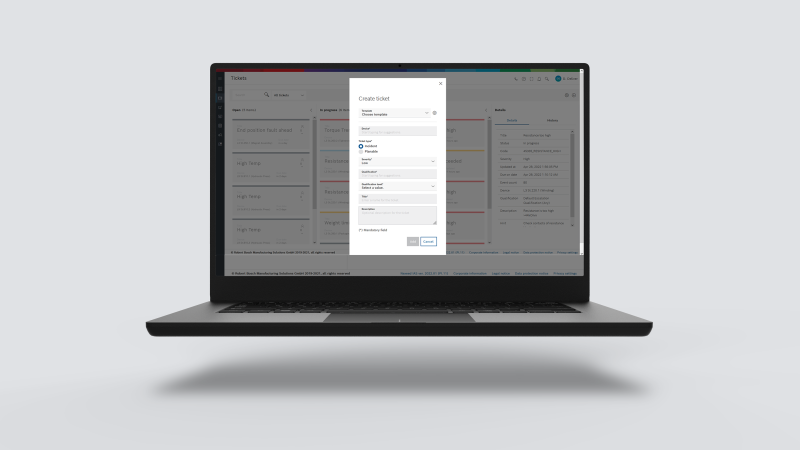

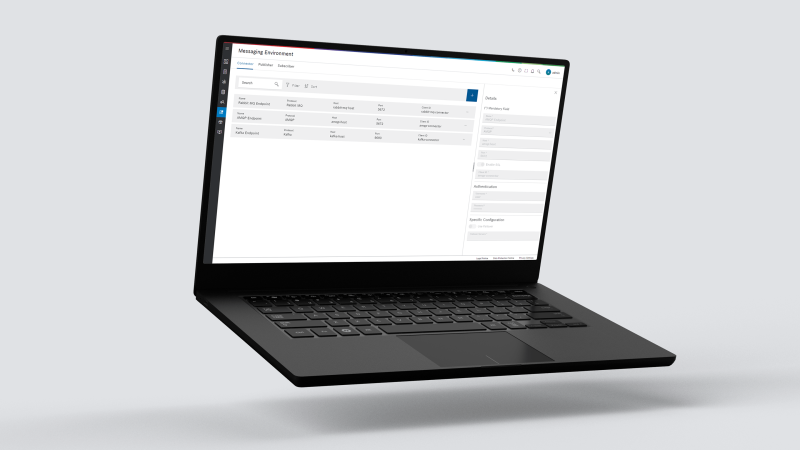

Main functions of Device Bridge

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET