Shift Book

From paper-based to intelligent shift planning

Intelligent shift planning for lower error susceptibility

Benefits at a glance:

From paper-based

to intelligent shift planning

Effective monitoring and documentation

of shifts and events

Focus on reasons for errors

and on their elimination

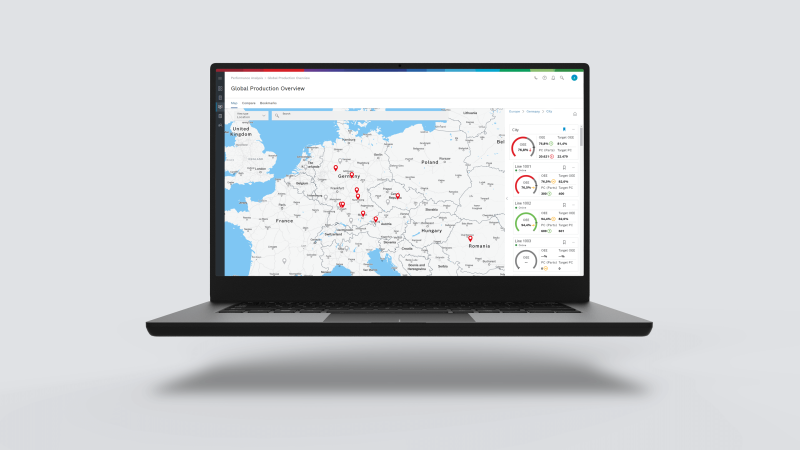

Shift Book: the central hub of local manufacturing

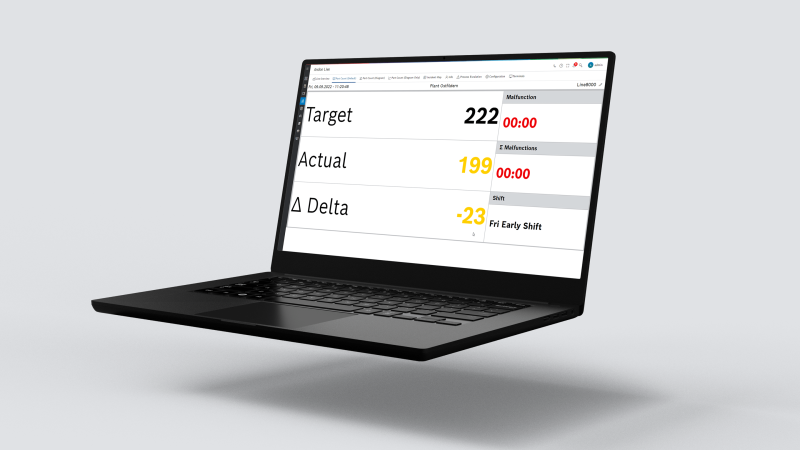

Many processes in production are still paper-based to date – from shift planning to planned downtimes through to recording unplanned production errors. As expected, the error rate is high. This is where the Shift Book module comes into play: in combination with the other modules from the Shopfloor Management application area, it creates a complete overview of planned and past production events.

Shift Book itself is the key element for local manufacturing. It is used for planning, documentation, and data collection. The data required for all further analyses, evaluations, and deductions is collected in the Shift Book module. This allows employees to better focus on the reasons for downtimes or process errors, as well as on eliminating the causes and achieving the relevant key figures.

Main functions of Shift Book

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET