Tool Management

Central management and documentation of costly tools and components

Reducing complexity in tool management

Benefits at a glance:

Centralized management and documentation

of all tools including components

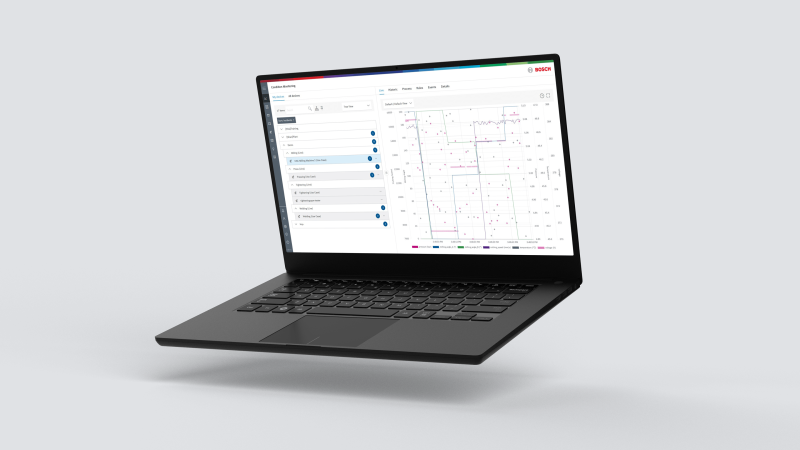

Automatic monitoring

of individual limit values with notification functions

Full transparency

regarding wear and upcoming maintenance

All tools and components at a glance at all times

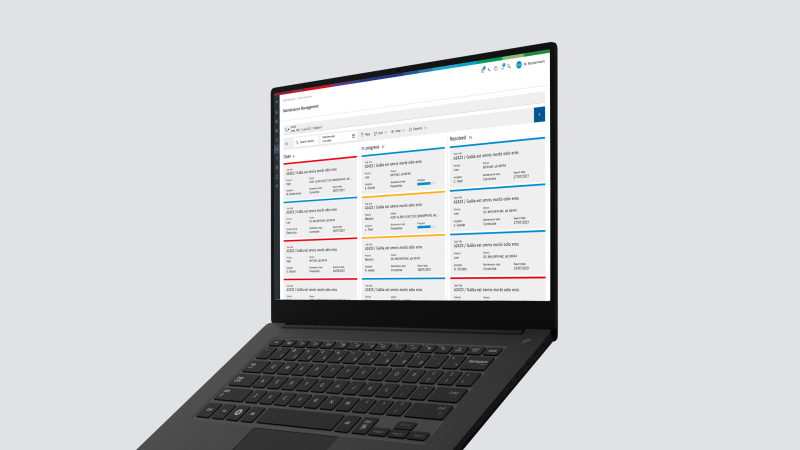

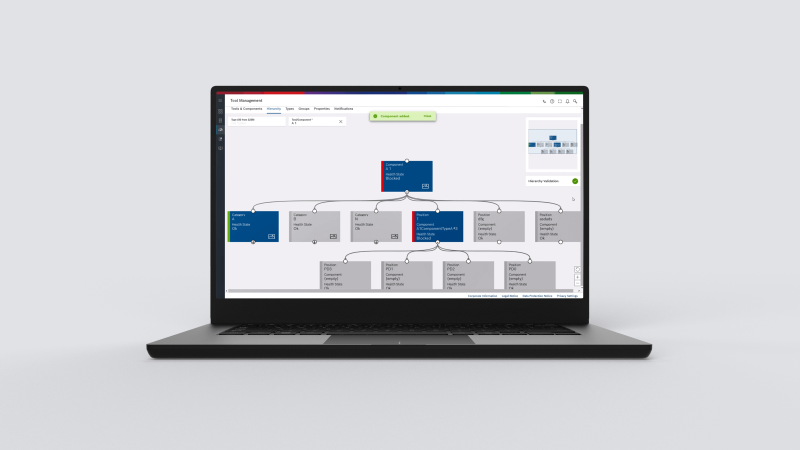

Where is a particular tool and what is its condition? Modern tools, for example in the field of plastic injection molding, have a high degree of complexity. They consist of a large number of components with different properties and individual degrees of wear. Instead of fixed maintenance intervals at the tool level, the individual tool components require a complex maintenance strategy. The Tool Management module offers a central location where the production tools in the system can be maintained and monitored via an interface. In addition, it provides an overview of their use. With Tool Management, all tools including their components are individually monitored using automatic rules.

Thanks to intuitive configuration management, the components and their connections to each other can be created and set up in a web interface. Individual limit value settings for each component with automatic notification reduce response times and prevent machine defects and quality shortcomings in the product. Tool Management ensures a high degree of transparency regarding the condition of the tools. The responsible groups of people are informed immediately by email when limits are exceeded and can respond accordingly. They also have centralized documentation at their disposal. This way, they can better plan maintenance intervals and component replacement, and reduce machine failures and downtimes to a minimum.

Main functions of Tool Management

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET