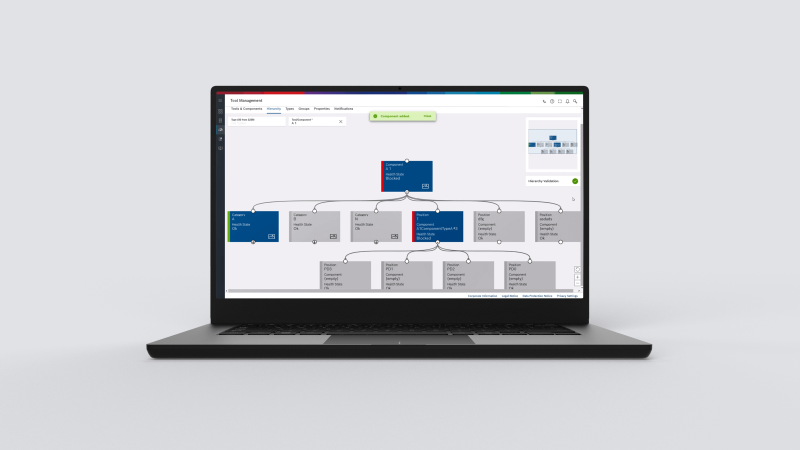

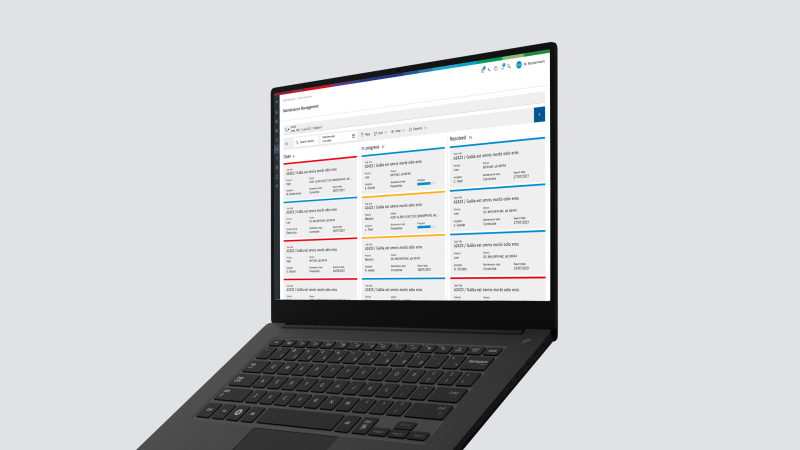

Maintenance Management

Efficient maintenance processes

Process maintenance orders faster and systematically

Benefits at a glance:

Less downtime and greater efficiency

in production

Reduced response times,

faster troubleshooting

Workflow optimization,

quick information accessibility

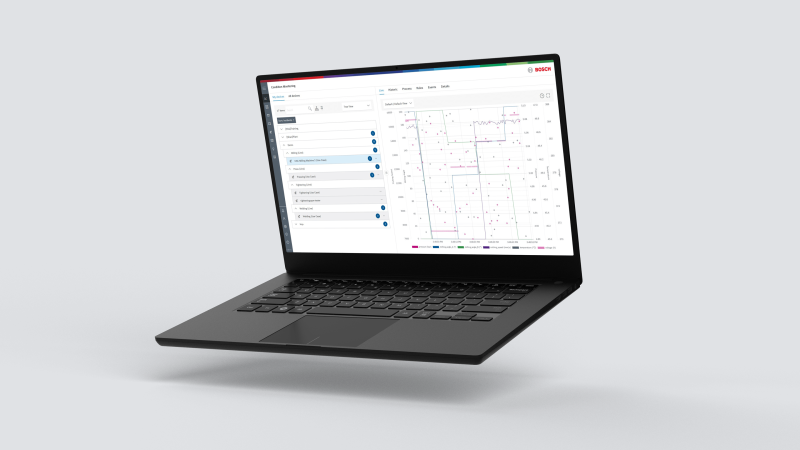

Corrective maintenance – faster, more effectively and more sustainable

Production failures cause high downtime costs. It is therefore particularly important to localize the causes of faults, to eliminate problems quickly, and to prevent future failures. That is the task of the Maintenance Management module. This web application digitally supports machine operators and maintenance staff in carrying out corrective maintenance faster, more effectively and more sustainably. Production employees can post open tasks and store them with relevant information such as the machine, priority, and fault description, including attachments such as images, videos, and sound files.

This in turn makes work easier for the appropriate maintenance experts. Service orders can be accepted and completed anytime, anywhere. In the future, preventive and autonomous maintenance will be successively integrated into the Maintenance Management module. Spare parts can then also be reserved and using external systems and their status can be checked; maintenance schedules can be created, and planned tasks can be processed successively. A notification system and connection to the error cause database are also planned.

Main functions of Maintenance Management

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET