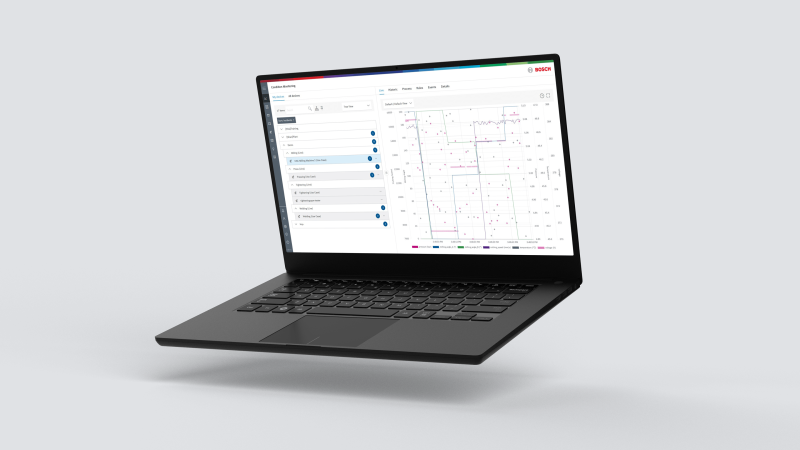

Condition Monitoring

For integrated machine monitoring

Permanent status recording of machines and systems for maximum transparency

Benefits at a glance:

Full transparency

Machine data and messages can be retrieved from anywhere at any time

Less machine downtimes

Fast reaction time in case of failures and analysis of frequent errors

Reduced expenses

Lower costs thanks to systematic production improvements

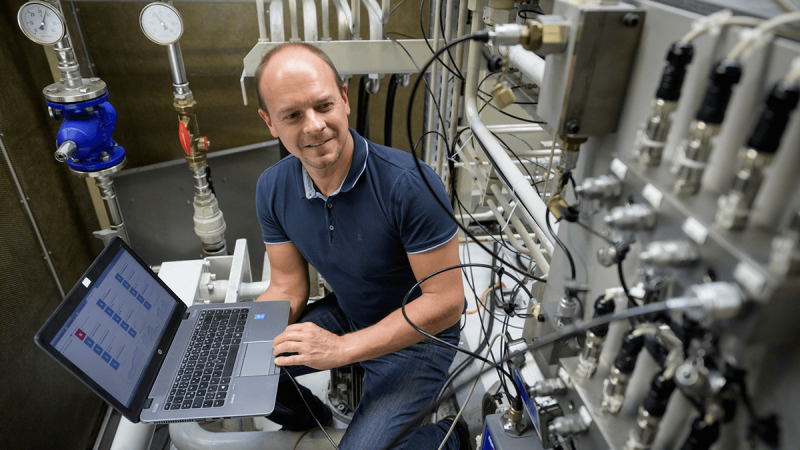

Condition Monitoring made easy

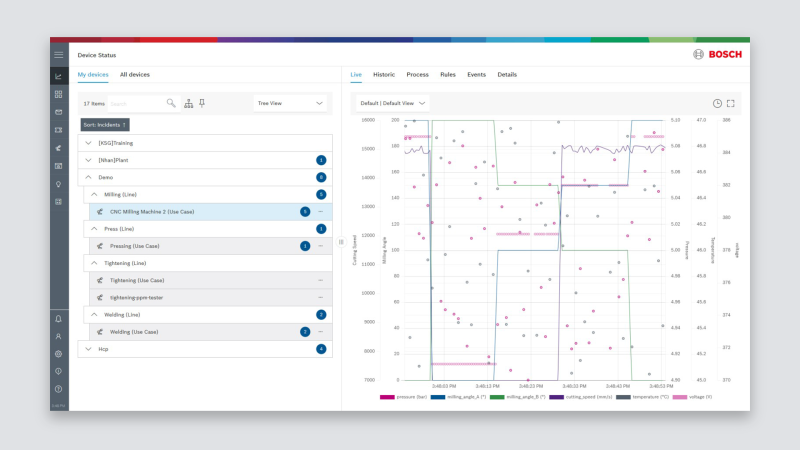

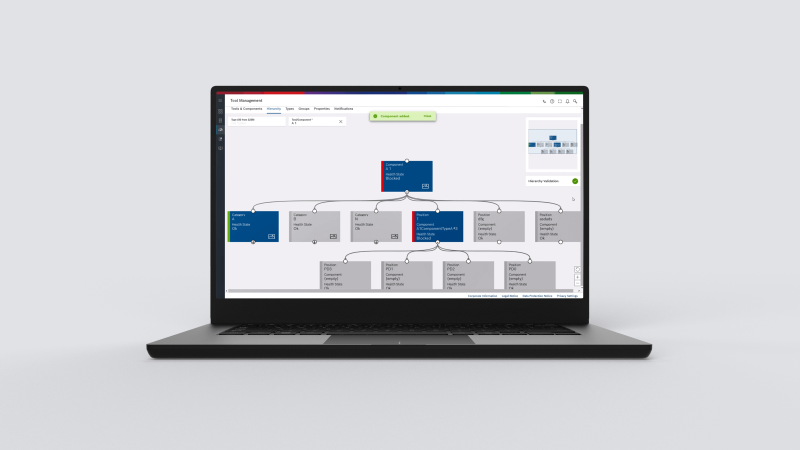

The goal of the Condition Monitoring module is to monitor and systematically optimize production. It collects production and machine data centrally, harmonizes it, and displays and processes it on any mobile device in a user-friendly manner. Maintenance engineers receive information on the machine status, process engineers on the production process and machine operator on errors or bad parts.

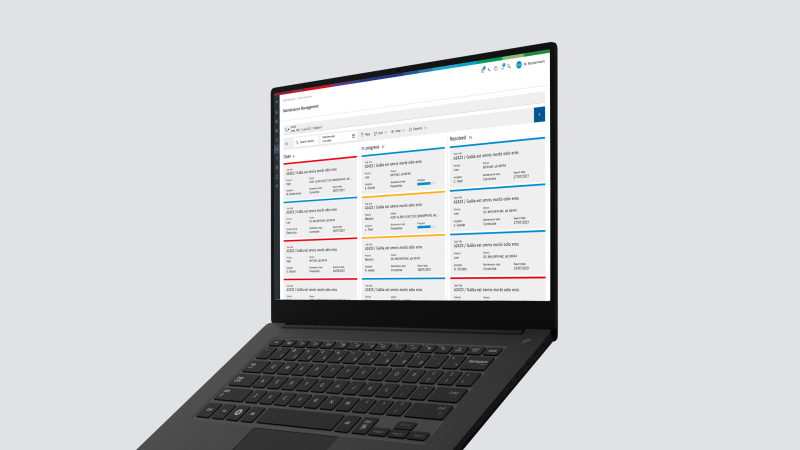

The current state of production can be recorded quickly. This greatly simplifies short-term decisions in the event of faults. The module also contains implementable rules and functions such as warning limits and a trend analysis. Users are provided with evaluation options such as sorting according to the frequency of an error message for long-term efficiency gains. This makes it easy to see where failures or bottlenecks occur regularly.

Main functions of Condition Monitoring

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET