Simulating instead of testing

3D simulation from Nexeed Automation shortens commissioning at SCHILLER AUTOMATION

Summary

Does it make sense to simulate the processes of special purpose machines? According to popular opinion, the development time for 3D simulations in special mechanical engineering is not worth the effort. SCHILLER AUTOMATION and Bosch Connected Industry dared to question this view. For a particularly urgent project, SCHILLER AUTOMATION tested the 3D simulation software from Nexeed Automation, which was specifically developed for special purpose machines. Based on the Control plus automation platform, the software creates a simulation in a very short time that can be used to test machine processes virtually. The outcome of the test project: despite the training effort, SCHILLER AUTOMATION was able to save four weeks of commissioning time.

The successes at a glance

Fast 3D simulation

Create a virtual depiction from CAD object data

Risk-free machine testing

Test machine processes virtually and detect potential problems early on

Easy handling

Virtual commissioning by PLC programmers

Starting point

An innovative spirit is just as important as customer wishes for special mechanical engineering company SCHILLER AUTOMATION. Bosch needed a line to pack automotive components into blister packs for a plant in Hungary – a typical project for SCHILLER AUTOMATION. However, the project team needed to catch up on some previous delays. The challenge: to be faster than the tight schedule. SCHILLER AUTOMATION – at this point already a long-time user of Control plus – approached Bosch Connected Industry to ask whether time could be saved in programming.

Solution

3D simulations help save valuable time during the commissioning of machines and lines, which engineers would otherwise need for on-site optimizations. However, such simulations usually involve a long development time and are generally not worth the effort for special purpose machines. “We have known SCHILLER AUTOMATION for a long time and knew that the company is very open to new developments. We didn’t hesitate to suggest our newly developed 3D simulation software to them,” says Benedikt Geissler, product manager at Bosch Connected Industry.

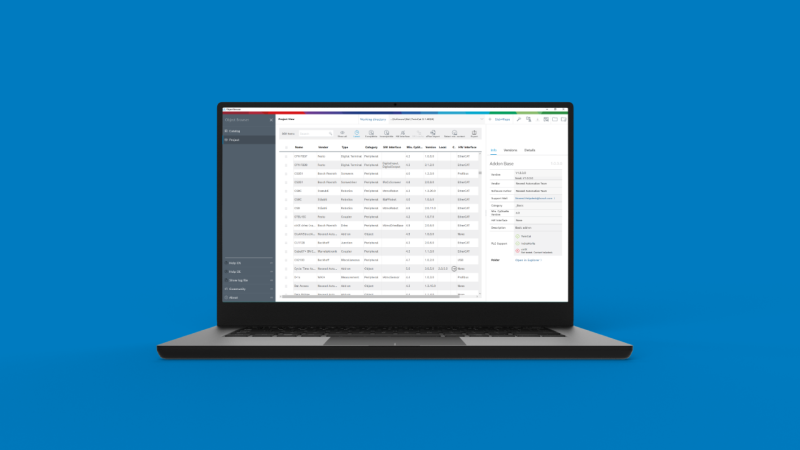

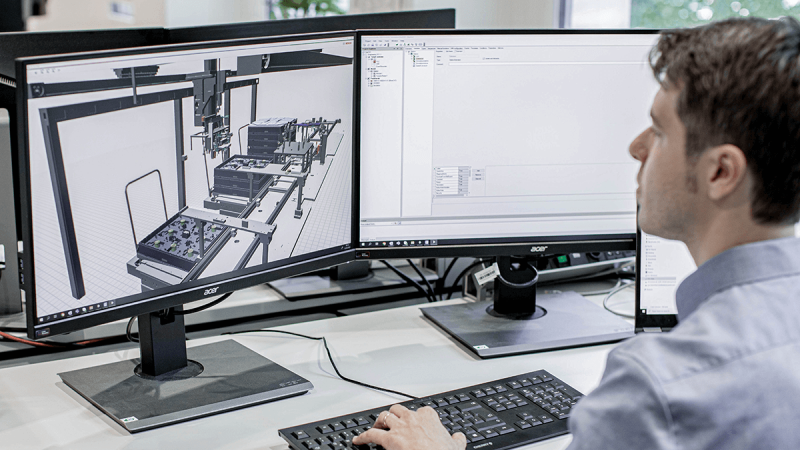

Nexeed Automation sets itself apart in one important feature: the 3D simulation is based on data from the machine configuration done with Control plus. The simulation uses the automation platform’s CAD object data of the machine components. Hence, a lot of work has already been done, which would take a great deal of time when developing virtual depictions of each component from scratch. The 3D simulation software simply imports the objects and uses them to create a three-dimensional model of the machine – a kind of digital twin – that can simulate all machine operations. Every process can be tested and optimized virtually – long before the real system is physically built.

In addition to the time saved, one of the greatest advantages is the 3D simulation’s possibility of risk-free testing: if something breaks during the test on site – e.g. a gripper collides with another machine component – this will involve additional costs and commissioning is delayed. With the 3D simulation, the programmers discover such errors in the virtual tests and can make adjustments at an early stage.

Bosch Connected Industry supported the project closely and provided SCHILLER AUTOMATION with an experienced coach, software engineer Ricardo Fernandes. Based on the CAD data for the machine configuration, the simulation was created in just a few days. SCHILLER AUTOMATION employees were able to directly test the automation software for their machine.

For the machine project at Bosch in Hungary, the use of the 3D simulation software was a complete success. It took about two weeks for the digital twin to be ready and for SCHILLER AUTOMATION to become familiar with it. Thanks to the 3D simulation, the engineer was even able to put the line into operation four weeks earlier. Despite the familiarization period, the new simulation software saved two weeks in total within this first project.

Thanks to the 3D simulation, we were able to finish commissioning four weeks earlier.

Outlook

This will not be the last time SCHILLER AUTOMATION uses the software, as Rainer Wolf, head of software engineering, concludes: “We look forward to using the 3D simulation software again in future projects and can also imagine introducing it to other parts of the group.” In the future, the 3D simulation will be available as studio software for all Nexeed Automation users. “This will enable our customers to create 3D simulations without much effort,” Benedikt Geissler promises.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET