The OSRAM Ticket Manager

An Industry 4.0 app for employees

Summary

Bosch and OSRAM have connected over 80 different machines, some older than others, at OSRAM’s Berlin location. The plant for xenon automotive lamps now has the “OSRAM Ticket Manager” (OTM), with which OSRAM supports its employees as it moves toward digital, flexible production. At the heart of this concept is a sophisticated selection of applications of the Nexeed Industrial Application System (Nexeed IAS). This system takes what can be highly varied streams of machine data and then coordinates, harmonizes, and processes them into useful information – based on rules and in real time. Workers can now simply consult an app for a status report on their machines and systems. It presents a clear overview of any upcoming tasks, such as maintenance work or resupplying materials, allowing them to be organized and assessed. The app also provides access to all information about key tasks.

What has the OSRAM Ticket Manager achieved?

The successes at a glance:

Ensuring that production runs on schedule

Transparency and consistently fast troubleshooting

Boosting efficiency

The best qualified and most suitable employee available performs repairs

Reducing costs

Lowering the cost of faults and errors – in machines and also in non-optimized planning

Open standards

Integrating more than 80 different kinds of machines

Background

OSRAM can look back at over 100 years of tradition, experience, and expertise. With in-house mechanical engineering and independent system development, OSRAM continuously assures the high quality of the products bearing its name. Its product technology is closely tied to the company’s mechanical engineering and the system technology it uses. In the past, OSRAM sought to continuously improve its product quality and productivity by using proven tools ranging from lean approaches and operational excellence to Six Sigma. The idea for the Ticket Manager has its roots in the new possibilities created by Industry 4.0, but exactly how to make it a reality was initially unclear. OSRAM needed a reliable partner with the expertise necessary to fulfill the requirements of the Ticket Manager:

- A smart central system to replace personal handling of individual machines

- A nuanced assessment of the condition of all machines

- Recognition of correlations in machine feedback

- A way to specifically assign maintenance and repair tasks

By fulfilling these requirements, the OTM system should enable efficient communication and set up new organizational structures in production to ensure greater decentralization, predictive capability, and mobility.

Solution

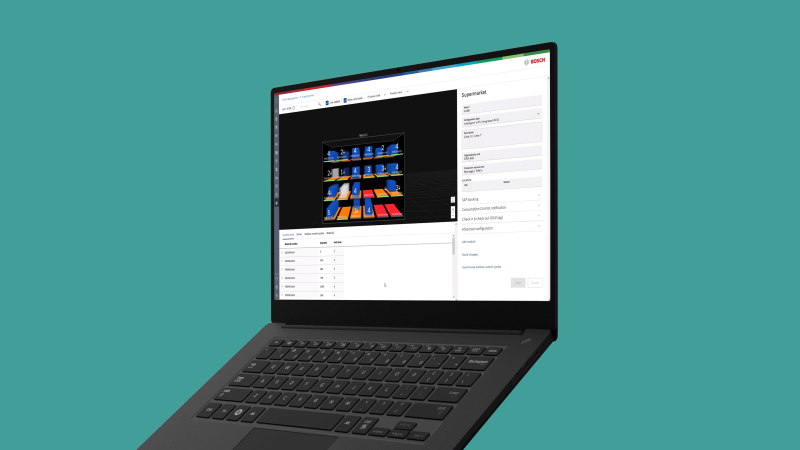

The technological core of the OTM is an application of the Nexeed IAS, which was extended to include certain project-specific functions, such as an app for mobile devices. The OTM is a crucial component of all communication in xenon automotive lamp production. It pools and harmonizes data from some 80 different machines before subjecting it to rule-based processing.

In the OTM system, OSRAM production employees and process experts configure complex rules and actively adjust them to current production conditions and the latest information. This turns raw machine data into specific, value-adding information. It also makes employee expertise – including on relationships among different machines – available transparently and automatically around the clock. And all of this without any software programming. As a result, it is easier to adhere to standards such as regular maintenance intervals. The system also automatically records error messages and categorizes their effects on production, making it possible to minimize machine downtime. One positive result is increased production efficiency.

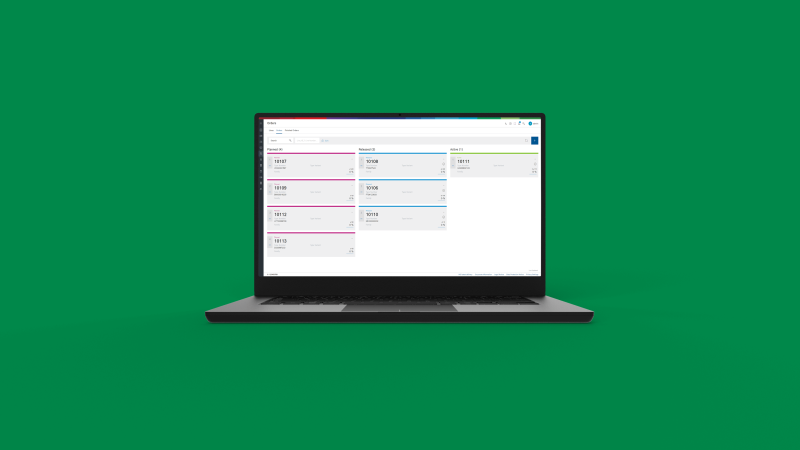

As the project also called for targeted allocation of repair and maintenance tasks, Bosch and OSRAM integrated a qualification matrix and the shift book into the OTM system by means of a database. Wherever machine operators, maintenance staff, or service personnel might be in the factory, the app keeps them constantly informed about the status of their machines and about tasks that need to be done – such as maintenance or repair work, resupply of materials, or resolving a machine fault. The system knows both who is best qualified for which tasks and who is available, allowing it to assign the right employee to the job. They can then accept the assignment, forward it, or escalate it. Besides delivering cost savings and productivity increases, the system also provides a basis for developing OSRAM Berlin’s service-oriented production organization along Industry 4.0 lines.

Outlook

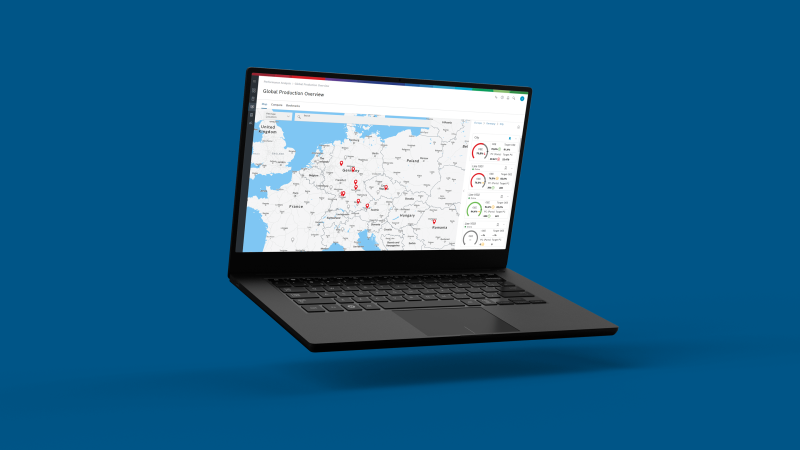

After its successful introduction in Berlin, the OTM will be rolled out to other OSRAM plants. The two companies will continue their excellent collaboration in new Industry 4.0 projects.

Remark on the software solution used: OSRAM is currently using the software solution Nexeed Production Performance Manager. The individu al applications Condition Monitoring, Process Quality and Ticket Management are being transferred to the Nexeed Industrial Application System, where they are developed further. The use cases described here can now be realized with the Nexeed Industrial Application System.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET