HBM: greater security and efficiency for state-of-the-art calibration systems

with software solutions of the Nexeed Industrial Application System

Summary

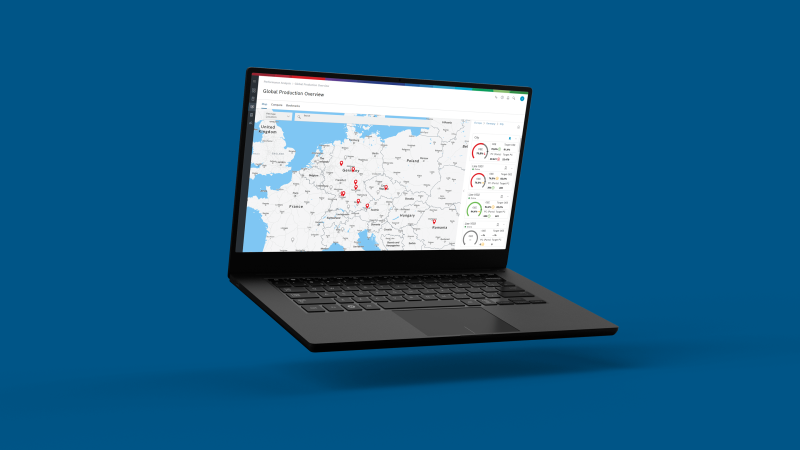

The internationally renowned company HBM offers accurate and reliable measurement technology products and services at 30 locations worldwide. HBM always keeps up with the times to meet increasing customer demands. This is why the company has chosen, among others, several solutions of the Nexeed Industrial Application System (Nexeed IAS) from Bosch Connected Industry for a simple and fast digitization of its calibration laboratory.

Combined with the state-of-the-art PMX amplifier system developed in-house and its own HBM cloud for site-independent data storage, the Nexeed IAS makes every calibration process transparent. The permanently running calibration system becomes an “open book” for process owners. Test chamber and load range data are transmitted to the software, which in turn reports faults and irregularities automatically. This improves the safety as well as the long-term efficiency of the calibration process. Downtimes can be minimized thanks to the predictive maintenance feature.

The successes at a glance

Improved system safety

Immediate notification when predefined limits are exceeded

Increased efficiency

Faster response by maintenance technicians due to automated issuance of service orders

Maximum system availability

Maximum system availability

Background

Since its establishment in 1977, the HBM calibration laboratory has been considered one of the most renowned and efficient facilities of its kind worldwide. HBM was also the first calibration laboratory ever accredited under the DKD (Deutscher Kalibrierdienst – German Calibration Service). Continuous investments in expanding production systems ensure the highest level of accuracy and the best way to satisfy growing customer demands. One key aspect of this is the digitalization of production and test lab operations.

In the case of the calibration system that handles sensors up to 33 tonnes or 330 kN, the parts to be tested are subjected to tremendous forces. Efficient control and safe operation must therefore be guaranteed at all times. Moreover, mechanical defects or faults in the climate control systems due to wear or operation errors result in high costs and downtimes.

Together with the experts from Bosch Connected Industry, HBM defined the requirements for the software solution:

- Seamless live tracking and tracing of the test processes

- A variety of analysis and evaluation options with alarms as well as e-mail notifications sent to internal maintenance technicians

- Trouble-free communication with all relevant components with a very brief implementation phase

- No modification of the existing system controls (PLC)

The overriding objective was maximum system availability. The test station should operate continuously with the shortest possible maintenance and downtimes. The chosen applications of the Nexeed IAS fulfill these requirements: The software solution can collect and analyze data sent from the sensors. Self-configured rules are used to send alerts in the event of faults or errors. Storing and evaluating historical data in clearly arranged diagrams also makes it possible to expose areas with the potential for optimization and to improve the system's effectiveness over the long term.

Solution

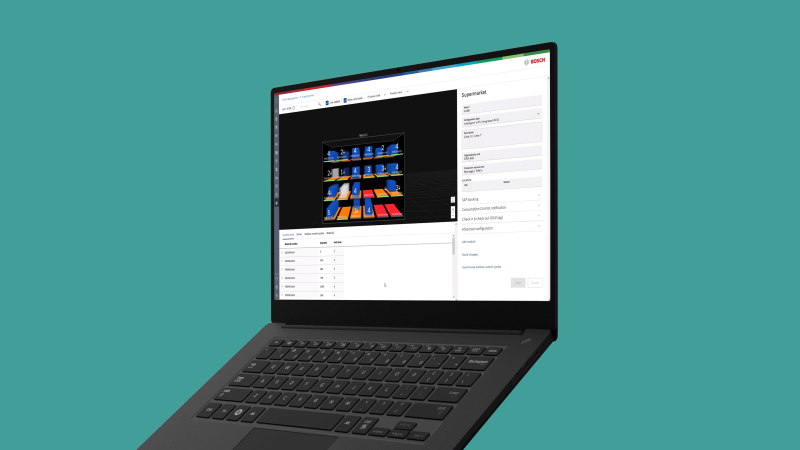

To achieve a safe, efficient and continuous testing and calibration process through the connection to the Nexeed software, it was necessary to examine the process in detail first. HBM chose the Starter Kit of the software, during which Bosch experts worked together with the responsible on-site personnel to analyze the system operating conditions. They further defined relevant positions for the installation of new measurement technology in order to record information such as temperature, humidity, inclination and vibration. In the future, camera-assisted monitoring of the test item will be added to the solution for optimum process control.

Together, Bosch and HBM looked for the right hardware and software: Large amounts of process and sensor data are merged in the in-house PMX amplifier system and transferred to the HBM measuring data acquisition software EVIDAS, which acts as an IoT edge, at a high resolution rate (several kilohertz). The data then continues to the HBM cloud storage in a compressed format and at a low transfer rate (a few hertz). The great advantage is that the data is available in the required level of detail depending on the use.

The locally available raw measured data serve the precise, AI-supported analysis, while the compressed data is transferred via the cloud to the Nexeed software. There, the information is turned into instructions, warnings or visualizations for evaluation purposes. The Production Performance Management Protocol (PPMP), an open transfer protocol initiated by Bosch for Industry 4.0 applications, ensures trouble-free communication between the different components.

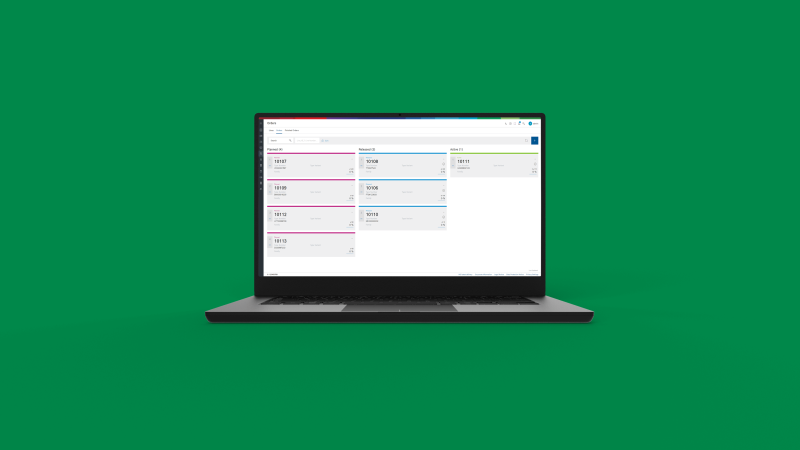

This offers a wide range of practical advantages: If predefined values, such as a critical temperature or period, are exceeded, the system automatically issues a warning message or sends a service order to a maintenance technician via e-mail. During the first days after commissioning, a downtime situation could already be prevented: An application of the Nexeed IAS reported a deviation in the tempering process, which previously could not have been detected. What’s more: Since the maintenance technician has the option to define and continually adjust complex rules, the software can detect trends in the available data indicating imminent defects or malfunctions earlier and more reliably than in the past. This makes it possible to further enhance the overall equipment effectiveness continuously and to minimize downtimes.

-

PMX amplifier system

Outlook

Since the applications of the Nexeed IAS software solution proved to be the ideal solution on the first test station, HBM would like to expand the system in the coming months to cover a total of 20 test systems with different types of problems. Additionally, HBM wants to use the software for its end-to-end solutions in test technology. This will give customers the ideal combination of hardware and software to implement very easily and quickly in their existing IT infrastructure.

Together, HBM and Bosch ensure that HBM customers receive not only innovative test and measurement technology with analysis and evaluation options, but also that the technology delivers maximum performance in complex software and hardware environments within the shortest amount of time.

Remark on the software solution used: HBM Test and Measurement is currently using the software solution Nexeed Production Performance Manager. The individual applications Condition Monitoring, Process Quality and Ticket Management are being transferred to the Nexeed Industrial Application System, where they are developed further. The use cases described here can now be realized with the Nexeed Industrial Application System.

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET