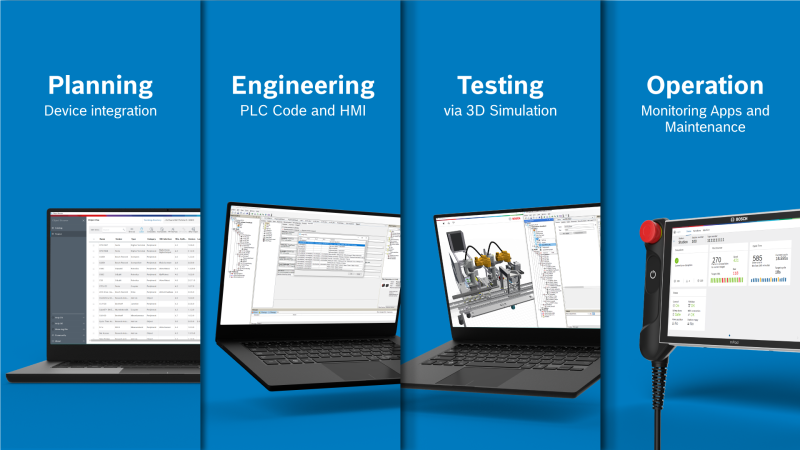

4 steps to greater efficiency in machine development

The efficient programming of machines is a crucial aspect of mechanical engineering, directly impacting productivity and precision. Specialized engineering software that supports the entire machine programming process, from the PLC to the HMI, is essential for achieving this efficiency with minimal programming effort. This software should enable quick and easy machine configuration. The following four steps outline the approach of such a software to generating machine code and HMI visualization without much programming effort.

Conclusion

Suitable software offers an innovative solution for reducing machine development time by up to 50%. It enables straightforward and rapid configuration of machines using pre-built and field-tested software modules. By distinguishing between manufacturer-independent objects and manufacturer-specific interfaces, developers can work flexibly and independently of hardware manufacturers. The software optimizes not only the development process, but also the subsequent operation and maintenance of machines. Faster device replacement, reduced programming effort, and automatic code generation lead to increased efficiency and a stronger negotiating position for mechanical engineering companies.

If you have questions

Jörg Scherrieble

Product Manager

+49(711)811-26274

Get in contact

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET