4 advantages of machine maintenance with Control plus

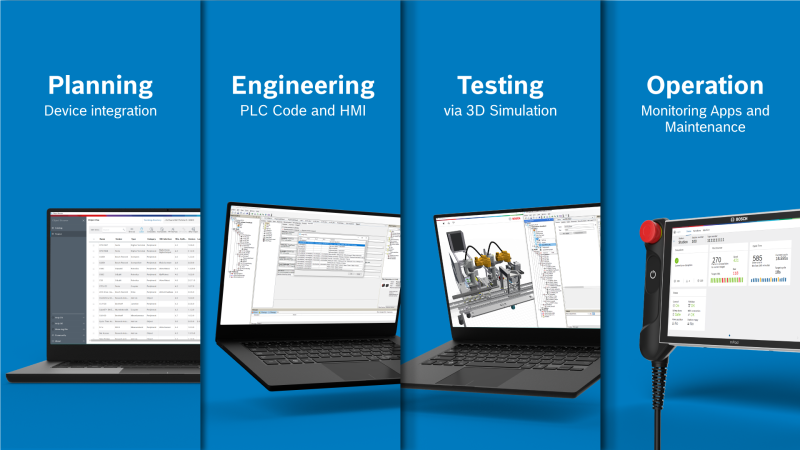

Bosch has an extensive global experience in operating machines and systems of various sizes and requirements. A recurring challenge is always the optimization of service and maintenance. Long familiarization times with the machine's PLC code, the availability of expert knowledge regarding the installed devices and the operation and diagnosis of the machine via the HMI are the biggest hurdles. To meet these and many other challenges, Bosch Connected Industry has continuously expanded and optimized the Nexeed Automation portfolio since 2014. This portfolio focuses on automation software in the areas of PLC and HMI. A central element is the engineering software Control plus, which enables machine builders to configure machines with ready-made software modules. The result is a high level of standardization in the development of PLC code and HMI.

Conclusion

The Nexeed Automation portfolio offers comprehensive solutions for the standardization and optimization of PLC and HMI in machines. These solutions simplify maintenance, increase the empowerment of associates and enable efficient error detection and resolution.

If you have questions

Jörg Scherrieble

Product Manager

+49(711)811-26274

Get in contact

Get in touch with us

Monday – Friday, 9 a.m. – 4 p.m. CET